The original Mazda rx7 was a hit from day one. lightweight, analog driving feel and good handling all contributed to a car that still to this day is fun to drive.

The original Mazda rx7 was a hit from day one. lightweight, analog driving feel and good handling all contributed to a car that still to this day is fun to drive.We get them into our shop on a regular basis with the number one issue is how they drive at our altitude and how to improve the experience.

Here we have a first generation Rx7 that was purchased new here in Denver and now passed down within the family. This car is all original with a new paint job and some ongoing maintenance along the way. The car did not want to idle / surging and running very rich (you could smell it).

First job, to get a compression test done to make sure the internals are solid. Result: over 120 psi on the front and over 116 psi on the rear, these numbers are excellent for any rotary engine of this vintage.

First, we found out that the carburetor had gathered enough grit/grime to keep the secondaries open just enough to mess with the idle. We took it apart, cleaned it up and had to take the whole carb down to its many pieces and run it through the ultrasonic cleaner.

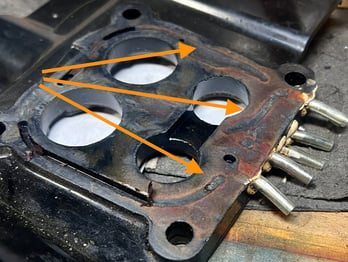

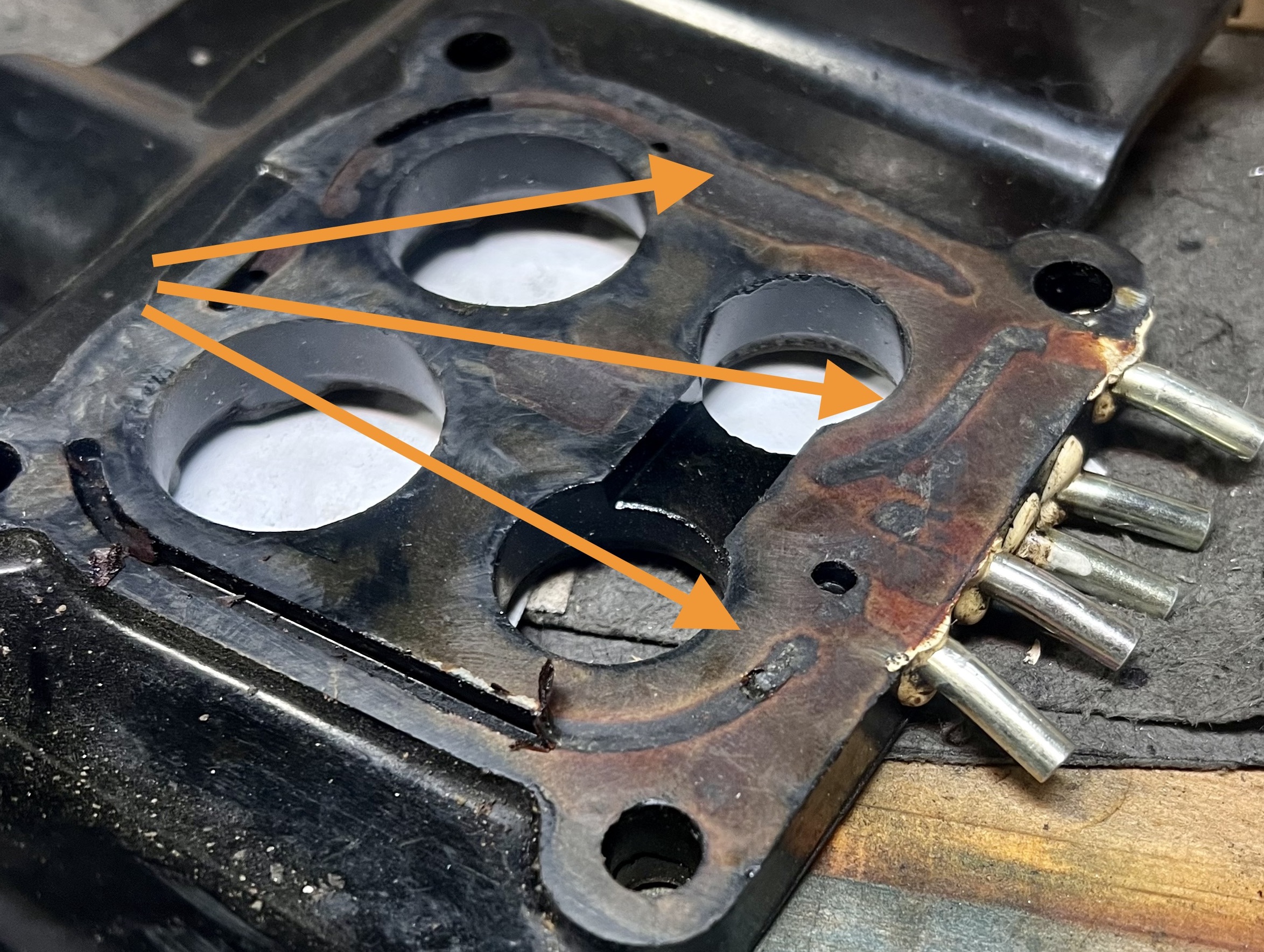

In our findings, it was noted that the phenolic spacer / heat shield showed another culprit of poor idle / performance. The 4 vacuum ports on the phenolic spacer were all plugged with varnish like material, this is not uncommon. Add to that the previous work done with the car had a set of gaskets that were not drilled for these vacuum ports. Details matter.

In our findings, it was noted that the phenolic spacer / heat shield showed another culprit of poor idle / performance. The 4 vacuum ports on the phenolic spacer were all plugged with varnish like material, this is not uncommon. Add to that the previous work done with the car had a set of gaskets that were not drilled for these vacuum ports. Details matter.We took the time to drill out the passages of the gasket, cleaned up the phenolic spacer and returned it to the intake along with the rebuild carb. Another issue that came up was the fact that the fresh rebuild kit did not fix everything, we found that we had to pull the accelerator pump jet out and clean them with nozzle brushes (very tiny ones) to make sure that the fuel was getting squirted down the primaries when demanded.

One last upgrade for our driving experience at 5000 feet of altitude. Taking the main jets out and filling them / redrilling them with smaller main jets to improve driving quality / performance. These carbs do have a small port for altitude adjustment (adding more air), yet do not work very well above 2000 feet.

Along with that major work, we went through and inspected the driveline, brakes, steering and checked for leaks. Repack the front wheel bearings (a must on these older cars with the 'very' small wheel bearings, adjusted the rear brake shoes (and the parking brake) along with fixing a small oil leak on the rear housing oil line.

The test drive: This car runs just like new, with good acceleration, smooth rotary power (and the occasional backfire, typical) and no rich fuel smell/stink that is common for NA carb Mazdas at our high altitude. We are now vacuuming out the AC to put in the 134 kit to get that blowing cold air. Solid outcome for a classic with many miles / smiles to come.

Topics: carb rebuild, compression testing