Performance Upgrades | Fuel pressure and the Rotary Engine

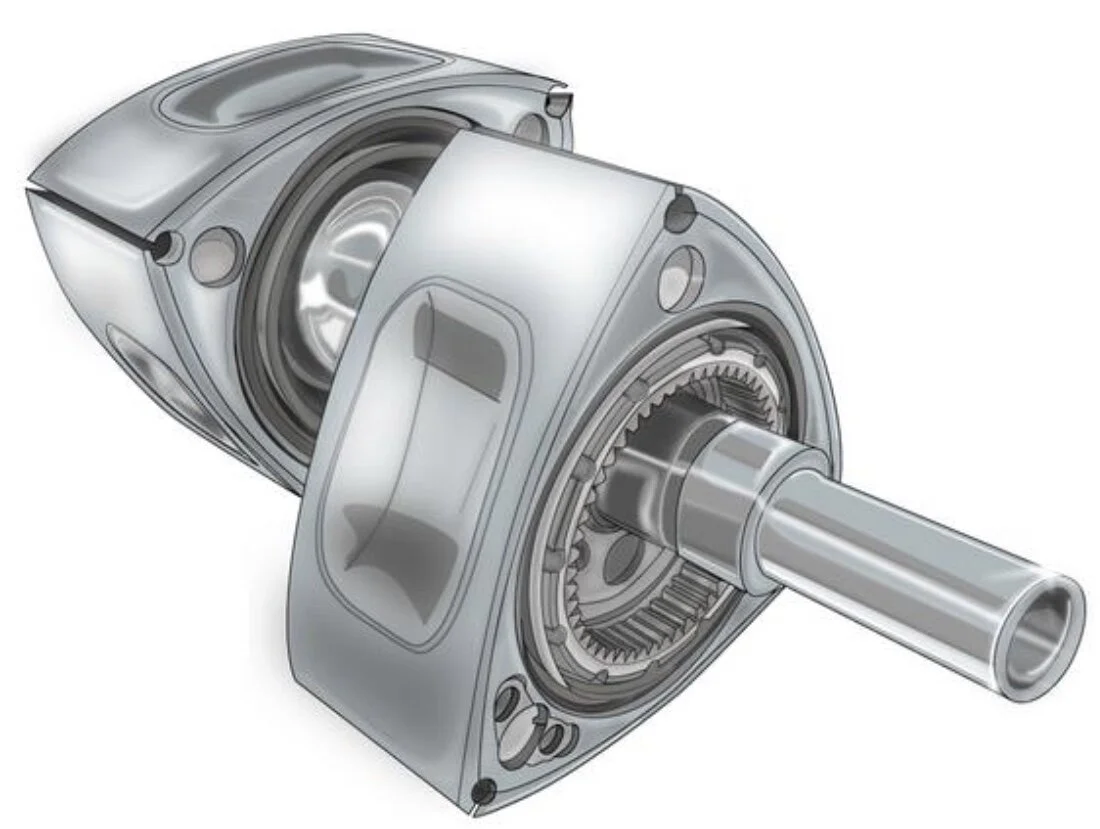

Fuel Pressure and Power | This is all about how the rotary engine is different than a piston engine.

Almost every street car runs about 43 psi of fuel pressure. I am sure that there are outliers and the Mazda Rotary Engine is one of them.

This is very important for your Mazda if you plan on making upgrades to make more power.

Fuel mapping is critical because the rotary engine has a rotating combustion chamber and utilizes fuel to cool the area. Our race 13B uses 70-75 psi depending on the ambient temperature here in Colorado.

Too much and too little can have dire consequences. The huge difference of a racing motor and street motor is the amount of time in WOT.

The long straights on race tracks like High Plains and Pueblo Motorsports park are good examples of where higher pressure makes sense in keeping the motor in the power and keeps it from overheating.

Remember, just because your performance car worked really well at lower altitudes, that doesn't mean it will work well in our thin air / high altitude / hot days. I’ve seen motors not start, run rough and wear out quickly due to poor tuning and lack of necessary upgrades.

Higher fuel consumption is a reality for making power gains, NA or turbocharged, it is just a fact. Putting that fuel where it is needed is where good tuning matters. The other component that is critical is fuel pressure, most shop builders believe solely in the 43lbs as 98% of cars are built that way. This is not acceptable for the rotary engine, get it right. Rotary motors have a long combustion chamber, thus are very sensitive to fuel pressure. Too little and it will lean out, too much and it will be hard starting warm.

For the carbureted low pressure rotary engined cars, they don't have the luxury of turning up the regulator for more pressure the way fuel injected cars do. This is where tuning via AFR / exhaust temp gauges is critical. On serious road race motors, having individual gauges for each rotor is expected. Remember, we are at 5000 feet of altitude, that is 15% less air so what you read on the internet rarely takes that into account for us at higher altitudes.

I like to tune each rotor to those specific numbers as they can fluctuate as much as 10-15%. That means a lot of fuel needed at 8500 rpm down a long straight.

Need help, just ask:

Topics: fuel injectors